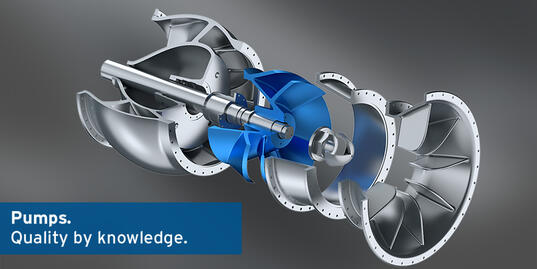

KÖSTER pumps – effectively good

We have been developing, designing and producing with

maximum depth of production for over 100 years. The interaction of

technical expertise, excellent materials from our own foundry and

state-of-the-art production technology guarantees the quality of our

machines.

We design and produce our propeller and mixed flow pumps for large and extremely large flow volumes (from 100 l/s steplessly up to maximum 8,000 l/s) with small to medium delivery heights (from virtually zero up to 30 m). We supply tailor-made machines that meet the special requirements of our customers.

Many of our developments have been patented. The fibre-repellent blade profile that effects passive self-cleaning of our machines and even today continues to dominate its respective market segment, is just one impressive example of the significant influence of a KÖSTER development.

When dismounted the propeller blades of our pumps can be loosened and adjusted in order to change the delivery rate and the delivery height of the pumps. Our pumps also offer the unique option of reverse operation. This active self-cleaning of the pump means that most failures can be remedied without the need of dismounting.

Our pumps can be used for a multitude of different pumping media. From surface water right on through to aggressive aqueous media such as the hot caustic soda solutions from large industrial washing plants. The materials used to produce our propeller pumps differ accordingly, of course. These range from grey cast iron right through to high alloy duplex stainless steel, which can even withstand the brine in desalination plants for seawater.

In the pump manufacturing sector the name KÖSTER stands for experience as well as for the reliability and strength of its machines. Our machines undergo continuous further development. They are always state-of-the-art.

Pump series VP

This type of pump provides high delivery rates at low heights and is used in pumping stations for irrigation and drainage, for precipitation and mixed water, in waterworks and in industrial water supply systems.

It achieves the lowest pump-down level of all propeller pumps and is suitable for the conveyance of pure or pre-treated, predominantly chemically-neutral fluids at temperatures of up to 60°C.

Particularly suited for pumping stations!

Pump series VPH

VPH Vertical propeller pump, suspended

This propeller pump achieves the highest delivery rate of all KÖSTER pumps. It is suitable for the conveyance of pure or pre-treated, predominantly chemically-neutral fluids at temperatures of up to 60°C. This type of pump is used primarily in pumping stations for irrigation and drainage, for precipitation and mixed water, in waterworks and in industrial water supply systems.

For the highest delivery rates!

Pump series VKP

Due to the different shape of their impellers, mixed flow pumps can lift very large volumes of water to delivery heights of up to 30 m.

Mixed flow pumps convey pure or lightly contaminated fluids, typically in pumping stations for precipitation and mixed water, hydroelectric power plants and other power plants, in docks and locks as well as in industrial water supply systems.

For docks, locks and cooling towers!

Pump series VTP

VTP Vertical submersible motor propeller pump

This type of pump is used typically in pumping stations for irrigation and drainage, for precipitation and mixed water, for recirculation, in flood protection systems and inland drainage as well as in industrial water supply systems.

This type of pump is suitable for the conveyance of pure or pre-treated, predominantly chemically-neutral fluids at temperatures of up to 60°C. The pumping medium should as far as possible be free of any coarse, fibrous contents - reverse movement is structurally not possible.

Fast installation – barely audible operation!

Pump series HUP

HUP Horizontal submersible motor propeller pump

Due to the horizontal orientation of the pump, the pumping medium flows in the discharge pipe without being deflected by the pump.

This type of pump is suitable for the conveyance of pure or pre-treated, predominantly chemically-neutral fluids at temperatures of up to 60° and is used typically in pumping stations for irrigation and drainage, for precipitation and mixed water, for recirculation, in flood protection systems and inland drainage as well as in industrial water supply systems.

With no deflection losses!

Pump series IBP

This circulation pump is suitable for the conveyance of water and aqueous fluids such as leaches, dilute acids, brines in closed pipe systems of industrial plants. This type of pump is used primarily in wastewater treatment plants, in which biological treatment is carried out in accordance with the activated sludge process, in which the flows (return activated sludge, recirculation) are moved permanently “in a circuit”.

It is equally suited for use as a booster pump for simply increasing the pressure in a pipeline.

Fits into pipe systems!

Pump series DIP

This circulation pump conveys aqueous fluids in the chemical industry, in plant constructions, for the treatment and purifying of drinking water and wastewater. It provides high delivery rates at low heights through the use of propeller hydraulics.

No pipes with a 90° bend angle are needed, so there are no comprises where hydraulic or structural requirements or questions of architecture are concerned.

Freely positionable!

Pump series UWP

UWP Recirculation propeller pump

This type of pump was developed in accordance with the individual specifications of a customer, among other things for use in aggressive, boiling hot caustic soda solutions.

This pump is an impressive example of our individual customer-orientated pump development – right down to the last detail.

In variable sizes – customised!

Pump series NPR

NPR Low-pressure recirculation pump

This horizontal propeller pump was constructed for extremely low delivery heights (up to maximum 1.5 m) and with two different installation positions.

All that is needed for installation under water with a submersible motor and an automatic quick coupling is a guide rod and coupling claws on the discharge side of the flange.

The important point for the version to be flanged into a dry pipe, i.e. above water, is that in addition to the high level of availability, the rotor assembly remains extractable. The angular gear and propeller are therefore designed in such a way that they can be completely swivelled out of a mounted pipe connection while the pump housing remains in the straight pipe line.

In addition to active sludge and nitrification / denitrification, the NPR also conveys precipitation, surface and river water, pre-treated wastewater as well as industrial process water at temperatures of up to 60°C and other aqueous fluids.

Keeps fluids moving!

Accessories / spare parts

As a system supplier we manufacture everything from a single source - from the smallest single part or spare part to the complete machine.

This also applies to standard accessories such as backflow traps, flat gate valves, fittings and moulded parts,

and also for special parts such as:

- Floor plates and floor plate frames

- Supporting frames

- Moulded pipe parts

- Wall ducts

- Consoles

- Conical connection pieces (floor level, coaxial, summit level)

- Special models on request

Installation / Service

We support clients and planners with our expertise from the very first idea of erecting a pump station, to the planning and on through to consultations when it comes to the selecting of materials.

The determination of the design and construction before the placement of an order and subsequent delivery and installation by our field engineers are closely dovetailed processes.

And what is more, maintenance, repair work and retrofitting- even decades after delivery - are included as a matter of course in our scope of performance. We also offer this service for the pumps of other manufacturers.