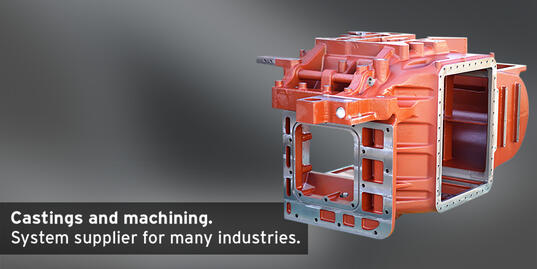

Castings and machining

Casting technology at its finest - maximum quality

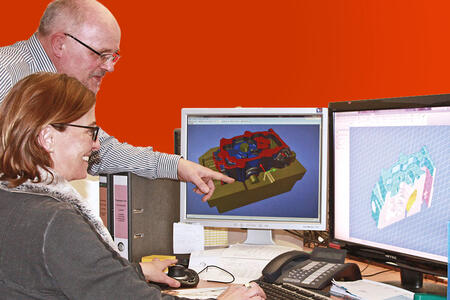

Experience and innovation – a good team

Casting technology has stood for competence, precision and quality at KÖSTER for more than 150 years. Just a few years ago we re-equipped our foundry with cutting-edge technology in accordance with the latest product requirements. It is approved as a material manufacturer and certified accordingly.

We are ideally equipped to meet all demands of the market.

Construction, model, components – all from a single source

We have developed during the course of history to become a system supplier. We realise projects from the constructive design phase of the components to the manufacture of the cast iron material, all steps of remodelling, processing and assembly and right on through to the final preservation. Our production and supply range is determined by the specifications of our customers.

The medium frequency induction furnaces in our state-of-the-art foundry ideally support the flexibility, high speed and consistent quality with which we always manufacture our products.

Our foundry manufactures the cast iron parts with a high degree of precision, in particular for customers outside of our company.

Storage and logistics – organised perfectly

Optimised logistics ensure prompt throughput times in our company. On request we also take over storage and logistical tasks for our customers.

Our scope of performance at a glance

- Development, consultation, design

- Model construction

- Castings

- Steel construction, sheet metal processing

- Mechanical processing

- Surface treatment

- Installation

- Storage, logistics

System supplier

for the following branches …

- General mechanical engineering

- Railway engineering

- Gas and diesel engines

- Gear and drive technology

- Industrial brakes

- Compressors

- Pumps

- Ship engineering

- Machine tools

- Wind energy

machining

Contact

Development, consultation, design

... in close cooperation with customers.

Model construction

... we carry out ourselves

High-quality castings

... from our own state-of-the-art foundry

Steel construction and sheet metal processing

... in our workshops.

Mechanical processing

... with maximum precision.

Surface treatment

... in our own paint shop.

Storage and logistics

... organised perfectly.

Installation

... e. g. an electric WE 20 cable winch.

Gearbox housing

... weight 201kg, width 870mm, height 350mm